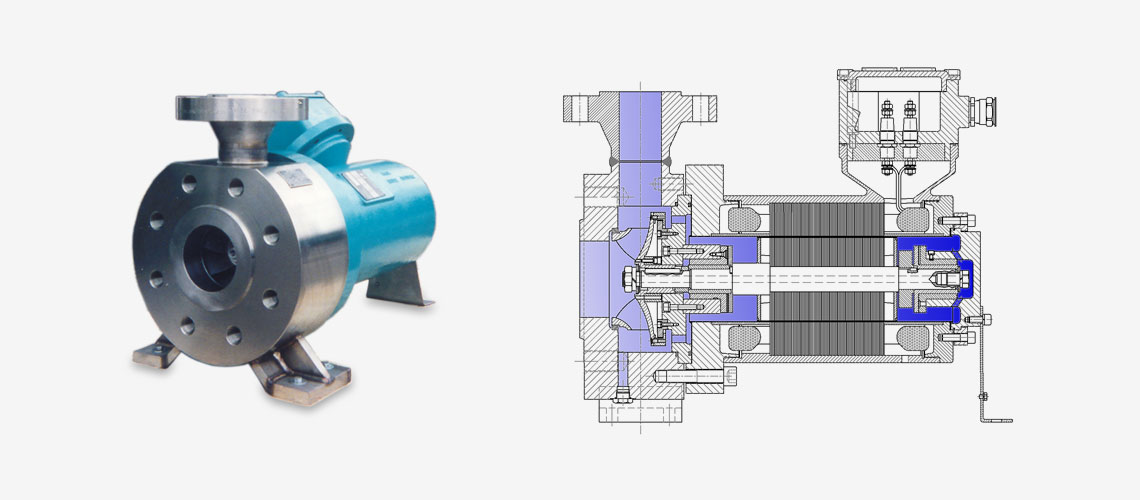

High pressure pumps:

A “high pressure” application means that the static overpressure test of the pump is above 75bar.

In this case, pressure is the most important factor for the pump design.

The construction of the machine is then carried out in accordance with the Pressure Equipment Directive (2014/68/EU).

- PUMPING RESTRICTIONS FOR HIGH PRESSURE LOOP:

On mechanical seal pumps, or on magnetic drive pumps, special precautions must be taken in order to avoid leaks due to a high suction pressure.

- OPTIMEX SOLUTIONS:

The compact monobloc design, which is completely sealed thanks to the double motor containment, permits OPTMEX canned motor pumps to withstand high suction pressures.